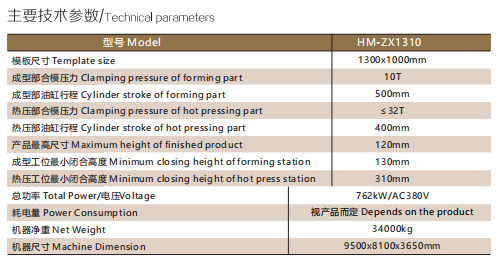

product introduction:

This model is a two-stage three-station pulp molding machine, which can be produced in a stand-alone or in-line mode, and is fast. It is widely used in the production of large quantities of products, such as molded tableware, disposable pulp molded cups, lids, etc. Consumable products, and the minimum draft angle is 0 degrees to start production and processing.

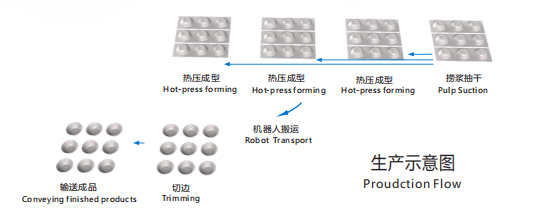

Process Flow:

1,The steel beam structure: adopts high-density carbon steel material after welding and annealing process, enhance the stability of the machine.

2,The parts directly in contact with wet pulp are made of stainless steel: such as forming platform, pulp storage barrel... etc.

3,The hot-pressing platforms of the machine are equipped with water cooling plates to increase the accuracy of upper and lower clamping.

4,Air passage system:equipped with positive and negative pressure control system, which is conducive to semi-finished products and finished product demoulding.

5,Cleaning system: the surface of the die is sprayed with high pressure water, and the rough edge of the product is sprayed with low pressure water。

6,The transportrobot is equipped with a vacuum sucker to take and discharge materials. After cutting, it is grabbed by a single shaft machine hand and put into the automatic lifting and receiving platform.

7,This machine adopts PLC+ touch screen man-machine system, hot-pressing time, platform position, suction time... and other production setting parameters.

8,Heat source: electric heating.

9,The whole machine is divided into two parts: the pulp suction part and the hot pressing part (including three groups of independent hot pressing forming stations). Pulp suction part: After the wet billet is sucked, it is pumped and pressed, and then sent to the hot pressing part through the transfer mold. Hot pressing part: transfer the wet billet to the hot pressing mold, and use the hot pressing and drying forming technology to form the mold through clamping, hot pressing, and baking. Then the mold is withdrawn, and the sliding table is moved out to the robot picking position. Three hot-pressing stations (one for three) are provided by one pulp suction part to work cyclically through the transfer mold. The handling robot directly sucks the formed semi-finished product onto the cutting machine. After the cutting is completed, the single- axis robot sucks out the finished product and places it on the receiving table for completion.

Proudction Flow:

Finished Product:

Note:The Whole machine does not contain heat insulation boards, heating plates, heating pipes, molds, mold top locks and external pipes.